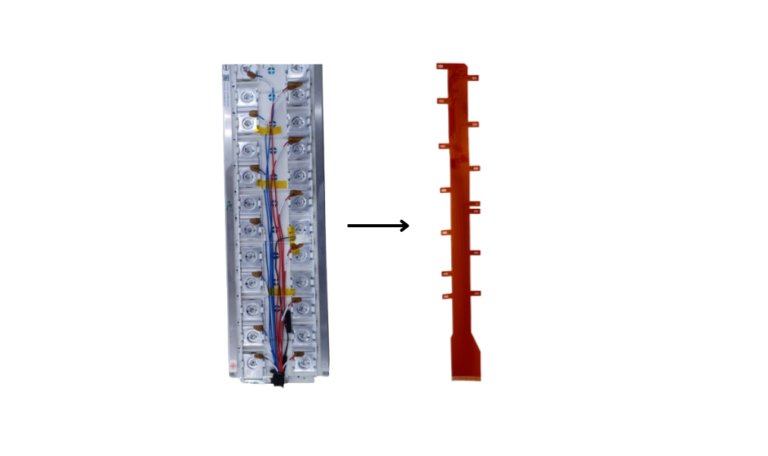

This solution allows the drastic reduction of battery connection systems dimensions, avoiding bulky cables. In this way, flexible printed circuits for batteries ecome the perfect mix of connectivity, performances and lightness,

Silga’s Gigaflex can be customized and adapted to any request both in terms of shape and of level of integration with sensor data such as temperature, state of charge and residual power to the BMS.

Our capabilites

- Up to 690 mm

- Up to 2000 mm

- Over 2000 mm

- Customizable formats

Special features

- Dual Access Copper connection in alternative to the use of nickel tabs with subsequent simplification of welding

- Potting & conformal coating

- Possibility to use RA Copper

- Integration busbar-FPC

Custom R&D projects for batteries:

- Integrated solutions for pressure and temperature sensors

- Measurement of stress forces

- IMS for thermal management systems

- Solutions for the connection among FPCs

- Modular integration among busbar + FPCs

Surface treatment on aluminum

Silga has developed an innovative surface treatment on aluminum that can be applied to Gigaflex to ensure optimal electrical contacting and weldability thorugh standard processes.

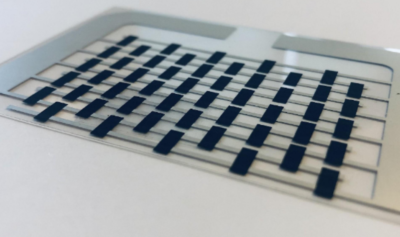

Flexible Heaters

FPCs for batteries solutions include Flexible Heaters, an innovative technology developed for the thermal management system of the same; in this way, the performance of the battery is improved, extending its life span, especially when it is located in areas with extreme weather conditions. Flexible heaters can be realized by using traditional etching or the new Printed Electronics, including the possibility of using PTC inks for self regulation of temperature. In addition, the Flexible Heaters “Made in Silga” offer the possibility of integrating special finishes to ensure excellent performance in any working condition.

Furthermore, Silga is working on the development of both rigid and flexible printed circuits solutions, also with the use of Printed Electronics for charging gates, the “inlets” that are upstream of the charging process of electric or plug-in hybrid vehicles.