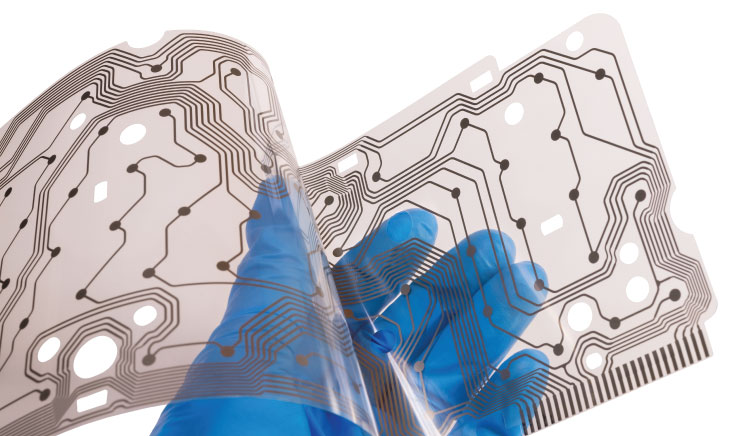

Flexible substrates and inks, that through an additive process can reproduce difficult electrical layout and thin tracks, are the key to include electronic components in 3D complex shapes, so that today we can co-mold flex PCB and plastic parts as in the case of Printed Electronics and of In Mold Electronics.

BENEFITS:

- Flexibility

- Thin Thicknesses

- Lightweight solution→ Mechanical parts and wiring reduction

- Green productive process

- Supply chain simplification

- Competitivenes

MATERIALS

- Polimeric substrates ( PET, PP, PC, …)

Other substrates: (paper, fabric or streatchable foils as TPU) - Inks (polimeric paste, including conductors, insulating and resistive inks)

-Silver Inks

-Copper Inks

-Silver inks filled wiht nano-particles to allow high definition tracks

-PEDOT:PPS

-PTC resistor inks

APPLICATIONS:

- Automotive

- Lighting

- Appliances

- Medical

- Wearable

- …