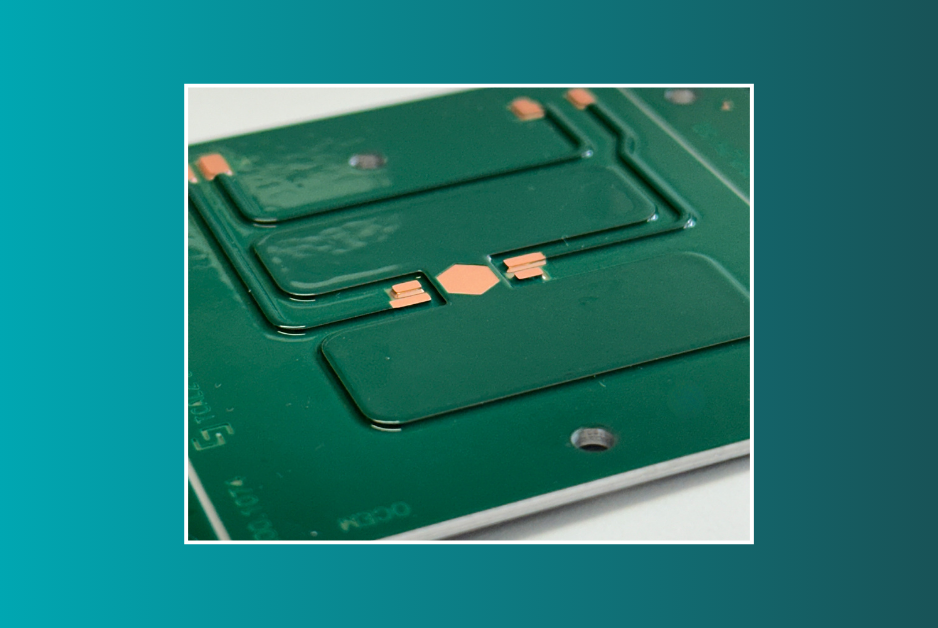

High-current applications require high-level materials and devices, able to sustain them effectively. And it’s right here that Silga Connect technology Insulated Metal Substrates (IMS) PCBs come into force.

IMS PCBs structure is composed of three different layers: a dissipating copper or aluminum substrate, a dielectric one which works as heat conductor and then a copper foil for the transfer of current which can reach up to 500 µm of thickness.

But where do Silga IMS PCBs can find application and what are their benefits?

- Automotive electronics as lighting, power modules, fan control

- Power electronics

- Industrial electronics

- EV chargers

- Lighting (outdoor, indoor)

- Telecommunications

- Consumer electronics

This technology has as its main purposes the efficient dissipation of heat caused by the great current flow and the stream of it. In this way devices can rely on excellent electrical insulation and lower working temperature, which results in an extended life of devices.

Contact us to receive more information about our IMS PCBs for your applications and read our brochure about this technology.