Today aluminum is playing an increasingly pivotal role in the evolution of electronics. Why? Because compared to copper, which is currently one of the main metals used in this field, aluminum is lighter, cheaper and less at risk of undergoing shortage. Plus, aluminum can be more easily recycled, making it the most recycled metal on earth, contributing to a more sustainable process.

In Silga we employ aluminum in different technologies and thanks also to our know-how in surface finishings we have developed an exclusive 100% Made in Silga finishing which allows the welding of PCBs made of aluminum and enhances the connectivity of it.

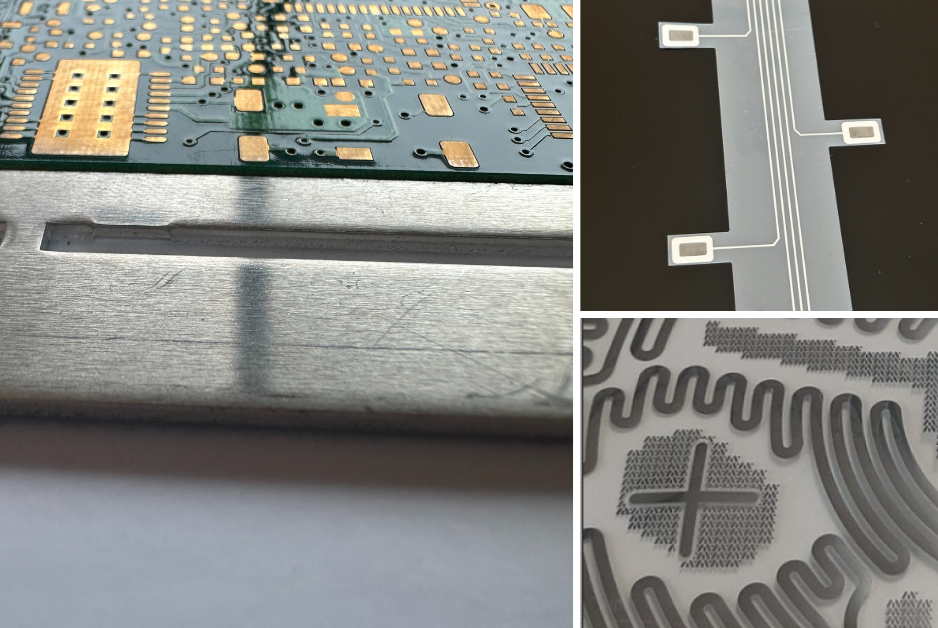

Using aluminum, we can realize Gigaflex, our FPCs for the sensorized connection of battery cells to the BMS, which can also include the dual access connection, avoiding the use of nickel tabs and Flexible Heaters.

Then, aluminum is also employed by Silga for IMS PCBs, insulated metal substrates, used for high-current applications where heat dissipation is needed. Here, a layer of aluminum is joined with a layer of dielectric material and then copper tracks to allow an efficient communication and heat dissipation.

Finally Silga has also developed Aluflex, the integration of aluminum tabs on specific areas where components (e.g. LEDs) are located with a Flexible Printed Circuit. In this way, flexibility and efficient dissipation are combined for multiple applications.

Discover with us all the solutions we can realize for your applications using aluminum.