New geometries, more lightness and thinness, alternative materials and greener productive processes are just some of the requests arising from several market sectors, from automotive to appliances, medical and wearable. So, how can we meet them efficiently?

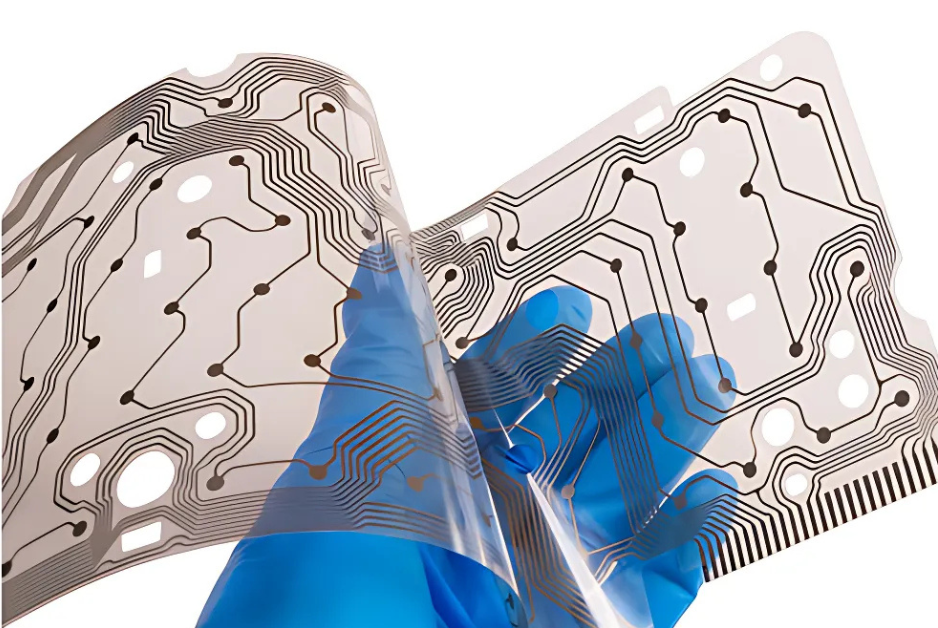

Silga Connect technology has developed the Printed Electronics, a cutting-edge technology which allows printing in addition conductive, resistive and special inks (stretchable, PTC…) to create tracks on a multitude of flexible, but also semi-rigid, substrates as PET, PEN, PC,TPU and alternative ones as fabric, paper and others.

Printed Electronics can also find application in the in-mold electronics, where tracks are printed on 3D shapes thanks to thermoformable inks, achieving a fully integrated device for interfaces, without the need of additional components. It is also the technology used for Flexible Heaters, as in the case of automotive interiors, wearable applications, medical devices and in all the applications where efficient thermal management and flexibility is required.

Talking about the Printed Electronics is undoubtedly necessary to mention the advantages of its productive process, its reduced steps and the saving in used materials, making it a more sustainable process when compared to others.

Furthermore, Silga is IATF 16949 certified and recently achieved also the extension of the IATF certification for touch foils that we realize in Printed Electronics.

Contact us to receive more details about Silga’s Printed Electronics and to get a customized solutions for you.